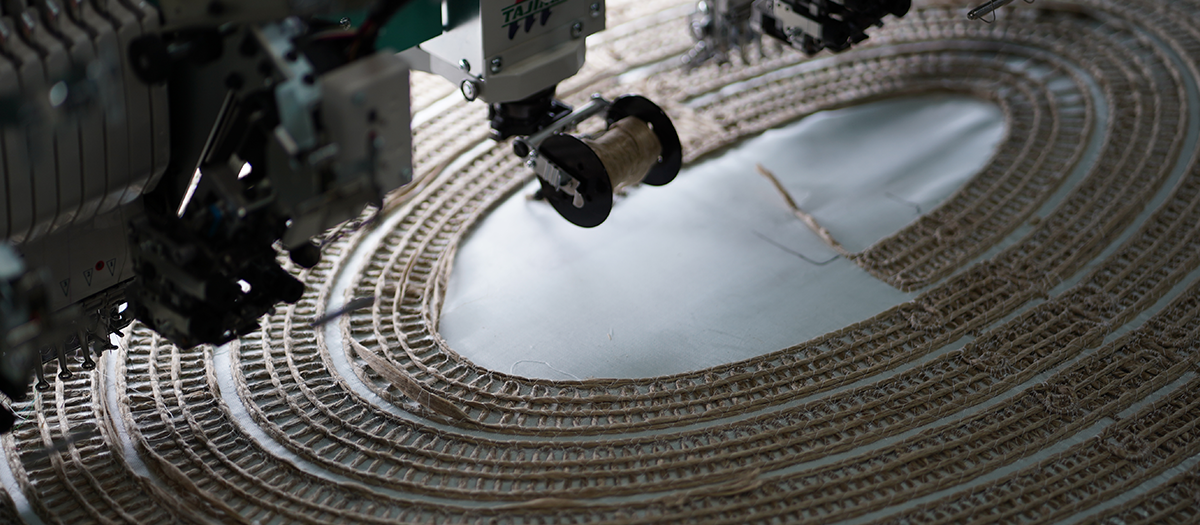

FlaxPack

As the use of Fiber Reinforced Polymers (FRPs) become increasingly popular in the built environment, steps in established workflows, including molding and transportation, continue to impose constraints on what is possible with the material’s fabrication process. This research aims to build upon previous studies of moldless fiber composites, replacing all dependencies on molds and formworks during the resin curing process by integrating compliant folding mechanisms into the flat preform to give shape to the final designed geometry. The flat pack components are material efficient in fabrication and furthermore, continue to perform efficiently when transported flat to the site for their final assembly into their programmed geometry. This form is locked into its bent active state through the use of a simple drawstring that can later be removed to revert the form back into its flat state. Additionally, this research demonstrates that flat packed elements can be deployed into aesthetically elegant solutions that embody structure, material, and form simultaneously.

Keywords: Fiber Reinforced Polymers (FRP), Moldless, Compliant folding, Flat pack, Bent active, Programmed geometry

Students: Kevin Saslawsky, Christian Steixner, Michael Tucker

Tutor: Vanessa Costalonga, M.Sc.

Supervisor: Jun.-Prof. Dr.-Ing. Arch. Hanaa Dahy

Seminar: Material and Structure, WS 21/22, University of Stuttgart.