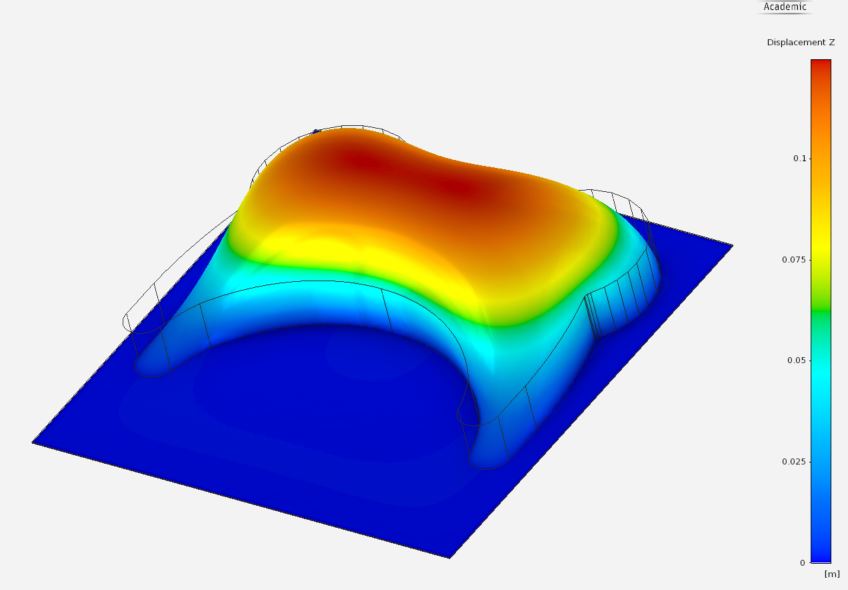

Air Pressure Thermoformed Chair

Unlike traditional blow process, in which polymer sheets are pressured to attain the shape of a pre-designed mold, this research produced forms generated from heated polymer sheets which were freely expanded under air pressure and which remained stiff and retains its shape after cooling. The goal of the research was also learning how to find the balance between surface tension of the heated area and attainable stable form without collapse. Factors and parameters such as temperature, gravity, thickness of material and cooling rate had to be taken into consideration. Prior to physical experiments, complex digital simulations using ANSYS AIM were made. The results, observations and simulations were used in a process of designing a chair produced entirely using selective areas of freely expanded polymer layer.

Students: I-Ching Lee, Sanoop Siby

Tutor: Jan Petrš, Piotr Baszyński

Suprevisor: Jun.-Prof. Dr.-Ing. Arch. Hanaa Dahy

Design Studio: Material and Structure, WS 18/19, University of Stuttgart.